Updated: 11/17/00

This is my 1928 South Bend 11" lathe. It is a model 84A with a 48" bed and a quick change gear box. I built the stand and table but the lath is excellent, original, and unrestored. I almost bought a 9" imported lathe but found this instead and am very pleased with the performance. A good quality, 78 year old lathe works better than most new lathes.

The stand is loosely modeled after drawings in the 1928 South Bend manual. I attempted to keep the "vintage" look but still implemented my own improvements. The stand is made of 4" steel channel. I designed an adjustable tensioner for the countershaft similar to a motorcycle chain tensioner. The motor is a 1960's GE 1hp saw motor. I plan on installing a variable speed DC drive in the future.

The wood is lumber grade Douglas Fir with an "Early American" stain and polyurethane finish. As I soon learned, you should age lumber before using it in this type of application as it can quickly shrink and develop cracks.

South Bend Lathe Specifications |

|

| Origin | South Bend, Indiana, U.S.A. |

| Date of Manufacture | 1928 |

| Model | 84A |

| Swing Over Bed | 11-1/4" |

| Length of Bed | 48" |

| Between Centers | 24" |

| Hole Thru Spindle | 7/8" |

| Swing Over Carraige | 7-5/8" |

| Power Required | 1/2hp (motor not inlcuded) |

| Weight Crated | 625 lbs. |

| Net Factory Cost | $349 (1930) |

| Threading | 2-112 tpi (48 different threads) | Motor | GE, 1hp, 1725rpm, 115vac, 60hz, 1 phase |

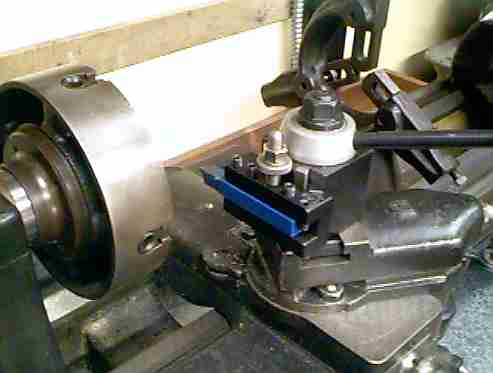

After using the lathe a little, I did make some "modern" concessions. I switched to a quick change tool post. It saves a lot of time and fiddling for most operations.

I used the leather belt originally, held together with clips and a pin. The belt could be easily removed but it did make a slight tick/thunk as it went around. I found some synthetic leather belting at the local equipment store. The thickness tolerance is tighter than the leather belt. I skived the ends on the mill and glued the belt after installation. I used contact cement and clamped it between two wood blocks until it set. Next time I'll try some other clamping arrangement as the pressure made the joint creep a small amount. Even so, it runs smoother and quieter now. The only drawback is that now the belt must be cut to remove it. Not a real problem since the belt does not normally have to be removed.

The motor has a slotted base to adjust the v-belt tension. You can also see the flat belt vertical adjuster on top of the upright that supports the backboard. All bearings are plain, even the countershaft. There is a small reservoir cast into the top of each countershaft journal. There is a felt wick between the reservoir and the 7/8" shaft. They must be oiled periodically.

| Design Pacifica |