Updated: 10/18/00

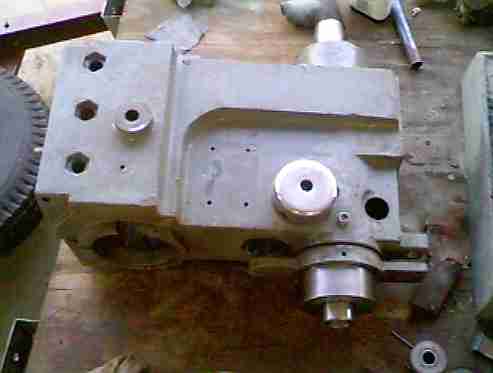

I found this used Excell EC-30B mill/drill for a good price. I read that even when buying a new imported mill/drill that you need to do quite a bit of clean up and rework to make it right. So, since the ways were good, I didn't see any major problems buying this one. The seller used his forklift to set the mill/drill on my little flat bed trailer. I tied it down securely for the 20 mile drive back to my shop. I immediately pressure washed it to get some of the grime off it and went to work with 3M pads removing the rust. It couldn't easily be moved it so I disassembled it while it was on the trailer. I should have taken a picture before I started the work but this is how it looked after some cleaning, rust removal, and disassembly.

The base had a lot of putty on the outside and slag on the underside. I spent more time cleaning it up than was spent on any other part.

This is the underside. It has adequate ribbing and some mass. The castings have less porosity than I expected.

This is the table after cleaning it up. I had to repair some porosity in this casting. There were a couple of blowholes in it. One hole went all the way through the table. I used JB Weld to fill it in and then I scraped it flush.

The motor ran OK but felt a little "crunchy". I disassembled it, cleaned it, replaced the bearings, and rewired it. It is a good size motor for this machine.

This is the head before I disassembled the spindle. I greased and oiled all the sliding parts and bearings before I reassembled it.

The quill feed mechanism uses a double reduction unit. It has a worm gear and then a rack. The .006-.007" of backlash is not a problem since it is taken up by a coil spring that pulls the spindle up.

After cleaning and painting all the parts, I bought a stand and started to assemble it. All parts are manageable by one person though some assistance would make it easier. The motor was the most difficult part to hold while inserting the bolts. I braced it on my shoulder. Since the complete mill/drill weighs over 600 lbs., it was assembled where I intended to leave it.

| Design Pacifica |